Dynamic Vapor Sorption

Invented in 1991 by Prof. Daryl Williams, Founder, and MD of Surface Measurement Systems, Dynamic Vapor Sorption is a groundbreaking technique for the physico-chemical characterization of solid materials. When compared with standard methods at the time, DVS characterized solid-state materials 20 times faster, with 20 times less sample, and 20 times more accurately. But how does DVS accomplish this?

What is DVS?

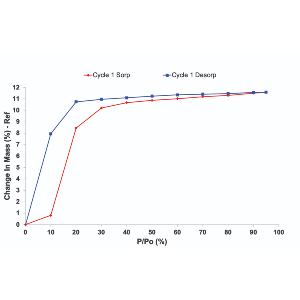

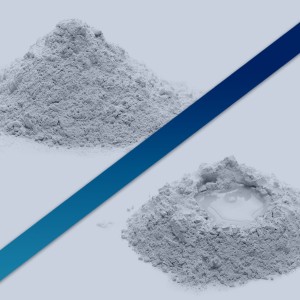

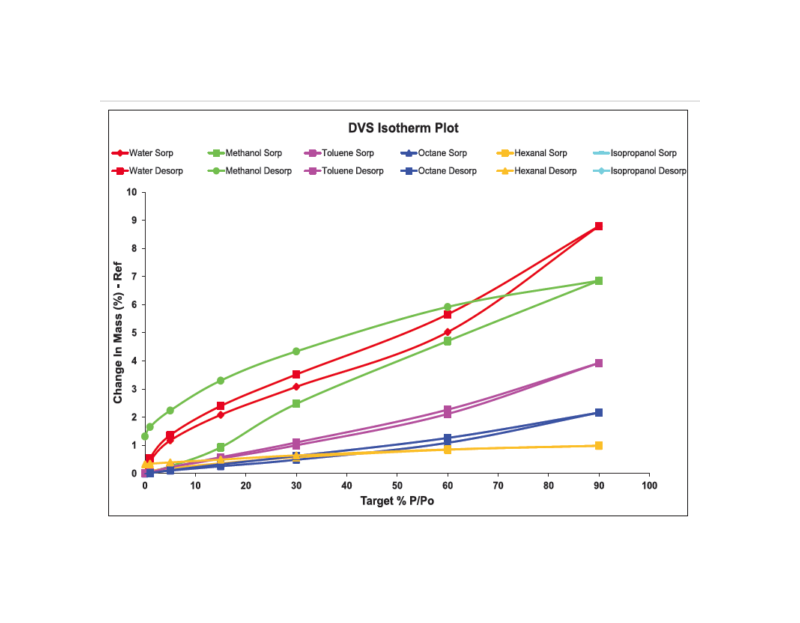

Dynamic Vapor Sorption (DVS) is a gravimetric sorption technique that measures how quickly and how much of a solvent is absorbed by a sample: such as a dry powder absorbing water. It does this by varying the vapor concentration surrounding the sample in a controlled environment and measuring the change in mass that this produces. While water vapor is most commonly used, the technique can also be employed with a wide range of organic solvents.

A valued tool in laboratories all over the world, DVS is employed across a range of sectors and applications within R&D, from polymorphism and compound stability studies to bulk and surface sorption effects of water and organic vapors. It is a vital part of quality control analysis techniques for formulation, scale-up, production, packaging, and beyond.

How does DVS work?

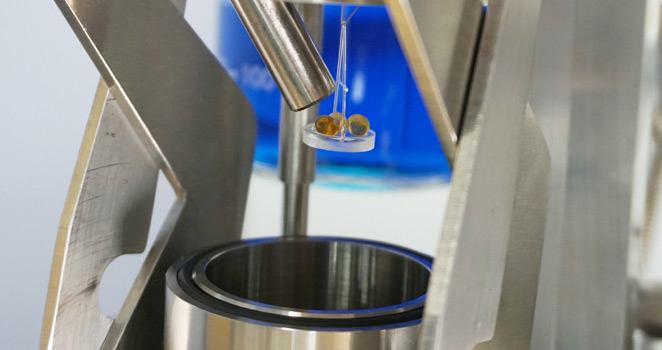

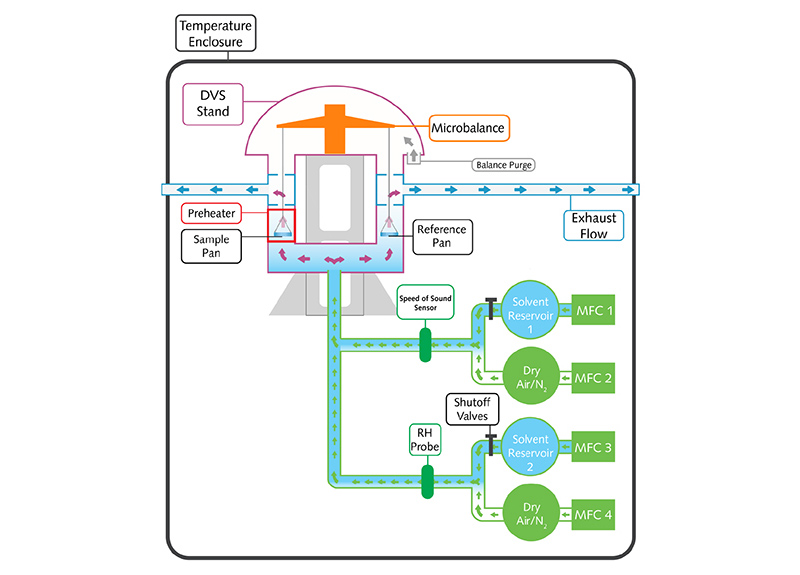

Dynamic Vapor Sorption rapidly measures uptake and loss of moisture or organic vapors by flowing a carrier gas at a specified relative humidity (or partial pressure) over a sample (which can weigh between 1 mg and 4 g) suspended from the weighing mechanism of an ultra-sensitive recording microbalance, the patented Surface Measurement Systems Ultrabalance. It is capable of measuring changes in sample mass lower than 1 part in 10 million, providing unrivaled long-term stability required for accurate measurements of vapor sorption phenomena, which may take from minutes to days to complete depending upon the sample size and material. Indeed, a major factor in determining the sorption behavior of materials is the need to establish rapid sorption equilibrium; therefore the DVS instrument allows sorption behavior to be accurately determined on very small sample sizes (typically 10 mg), thus minimizing the equilibration time required.

The DVS instrument is fully automated through purpose-built DVS control software package, providing a flexible and easy-to-use interface for setting up and running sorption/desorption experiments. In addition, the DVS Data Analysis Suite provides a powerful environment for rapid plotting and quantitative analysis of data.

The benefits of Dynamic Vapor Sorption?

Dynamic Vapor Sorption in action

Surface Measurement Systems have developed and engineered a range of innovative DVS instruments. With a variety of capabilities, we can offer solutions that can serve in any sorption experiment, and meet the logistical needs of any laboratory. Find out more about our DVS range to see why we’re the first choice in sorption in laboratories around the world.