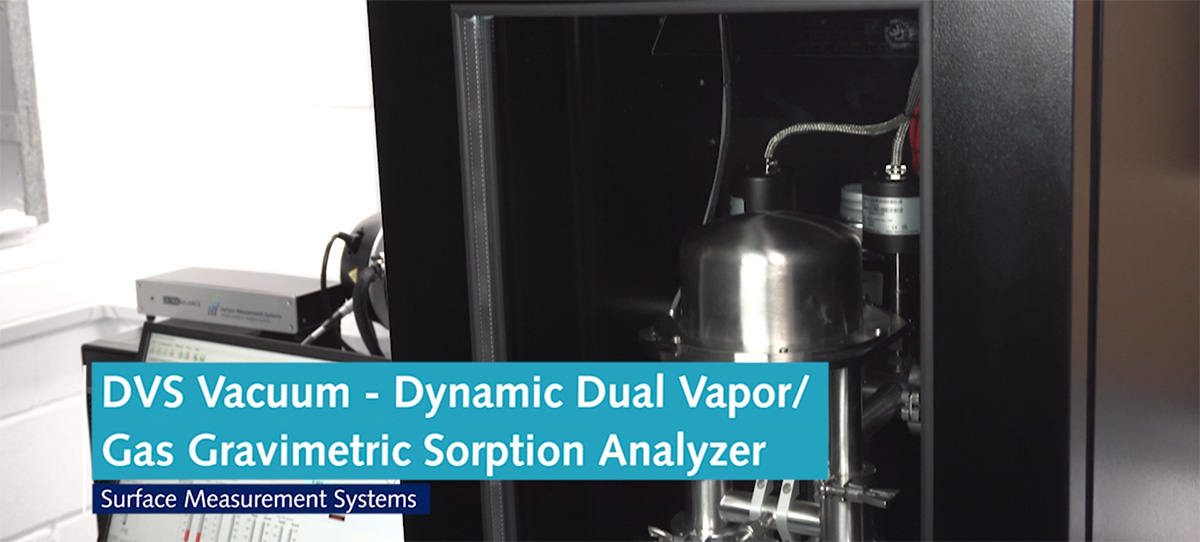

DVS Vacuum

Gravimetric Gas/Vapor Sorption Vacuum Analyzer

For the measurement of kinetics and physiosorption isotherms of Zeolites, MOFs, COFs, Carbons, and composite materials, there is no better instrument available than the DVS Vacuum.

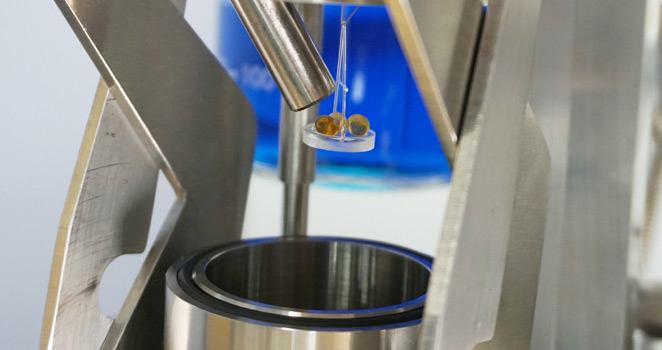

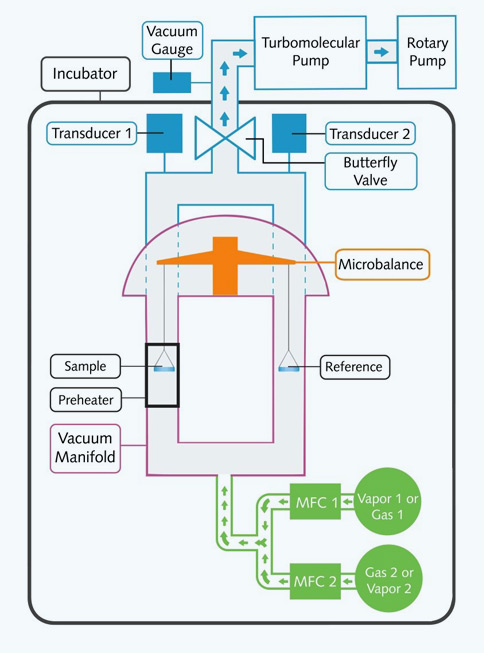

Designed for single and multicomponent vapor/gas sorption analysis, the system offers precise control, accuracy, and measure of temperature and pressure while recording the changes in sample mass.

The DVS Vacuum produces its vacuum with a combination of roughing and turbomolecular pumps for its operation. Maintaining thermal equilibrium throughout the vacuum chamber, including the sample, pressure transducers, vapor/gas delivery systems, and solvent flasks, the system enables smooth operation over the entire temperature range (10-70 °C) without risk of condensation.

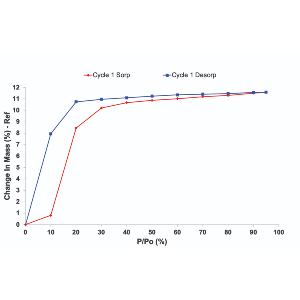

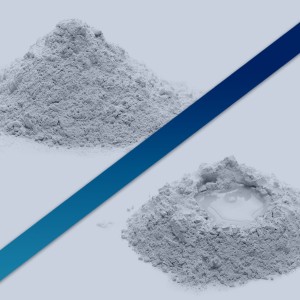

The system introduces partial pressures of water or organic solvent under a vacuum to minimize their impact on the structure of a material. The analyzer then measures true water or organic vapor sorption isotherms without unnecessary interference from a carrier gas. In addition, it allows us to study the drying kinetics of pharmaceutical powders, greatly expanding the applications of the instrument.

Gravimetric Gas/Vapor Sorption Vacuum Analyzer

Discover what makes the DVS Vacuum one of the most unique sorption measurement instruments in the world.

Find out more about the DVS Vacuum

To find out more details about the world’s most advanced vacuum DVS instrument, or enquire how you can bring its incredible capabilities to your lab, simply fill in your details below.